Setting Up Your 3-Ply Surgical Mask Manufacturing Unit In India (Detailed Guide)

Introduction

The demand for reliable personal protective equipment (PPE) is a constant in our world. Manufacturing 3-ply surgical masks presents a significant business opportunity, especially when approached with a well-defined plan. This comprehensive guide provides a detailed blueprint for establishing your own surgical mask manufacturing unit, drawing directly from industry-standard project feasibility reports to give you a realistic and actionable roadmap. We’ll break down every step, from initial planning to financial projections, using insights from a sample project report to illuminate the path to success.

1. Project Conceptualization and Feasibility

Before you invest time and resources, a robust feasibility study is crucial. The attached project report serves as an excellent template. Key aspects to consider:

- Product Focus: Surgical 3-Ply Masks: Our focus is on standard surgical masks, essential for medical and general use.

- Objective: Primary objective is to create a viable and profitable manufacturing unit.

- Scope : Project concept development, start-up, marketing, finance, and management. This blog post will mirror this scope to provide a holistic guide.

- Customization: Note that the project report explicitly states, “[We can modify the project capacity and project cost as per your requirement. We can also prepare project report on any subject as per your requirement.]” This highlights the importance of tailoring your plan to your specific needs and scale.

2. Financial Planning: Costs, Investment, and Funding

Understanding the financials is paramount. Let’s delve into the numbers from the project report:

- Project Cost: ₹18.05 Lakhs (Approx.): This is the estimated total investment. Breakdown :

- Land: ₹4.00 Lakhs (Option for Own/Rented – factor this into your plan)

- Building/Shed (1200 sq ft): ₹7.50 Lakhs

- Plant & Machinery: ₹5.55 Lakhs (Specifically, an “Inner Ear Loop Face Mask Making Machine” is listed at ₹7.5 Lakhs in “PLANT & MACHINERY” – this is a slight discrepancy in the report, clarify machinery costs during your planning).

- Furniture & Fixtures: ₹1.00 Lakh

- Working Capital Requirement: ₹5.55 Lakhs

- Means of Finance :

- Term Loan: ₹11.25 Lakhs

- Own Capital: ₹1.81 Lakhs

- Working Capital (Bank Finance): ₹5.00 Lakhs

- KVIC Margin Money: “As per Project Eligibility” – Explore government schemes like KVIC for potential subsidies.

- Profitability Projections : The report provides 5-year projections. Key highlights:

- Gross Profit Margin: Increasing from 32.53% in year 1 to 38.95% in year 5.

- Net Profit Margin: Growing from 4.5% to 15.2% over 5 years.

- Break Even Point: Around 39% capacity utilization (Year 1). This is crucial for understanding your risk and required sales volume.

- Debt Service Coverage Ratio (DSCR): Consistently above 1.5, indicating healthy cash flow to cover debt obligations (Reference: CALCULATION OF D.S.C.R). Average DSCR is 2.36.

3. Infrastructure and Location :

- Space: 1200 sq ft is suggested. Consider layout for:

- Manufacturing Area (ideally cleanroom environment)

- Raw Material Storage

- Finished Goods Storage

- Office/Admin Area

- Utilities (Power, Water)

- Power Requirement : 6 KW. Ensure stable power supply. Consider backup power (DG set – as mentioned in COMPUTATION OF ELECTRICITY) for uninterrupted production.

- Location: Factors to consider:

- Proximity to raw material suppliers.

- Accessibility to transportation networks for distribution.

- Labor availability.

- Local regulations and zoning.

4. Machinery and Equipment Procurement

- Core Equipment: “Inner Ear Loop Face Mask Making Machine” – This is your primary investment. The report quotes ₹7.5 Lakhs. Research different manufacturers and models to find the best fit for your capacity and budget.

- Capacity : The machine in the report has a capacity of 24,000 masks per day (50 pcs/min, 8 hours/day). This translates to 7.2 million masks per annum.

- Ancillary Equipment: Factor in costs for:

- Air Compressor (for machine operation)

- Packaging Machine

- Quality Control/Testing Equipment (optional but recommended for certifications)

- Material Handling Equipment (trolleys, etc.)

5. Raw Material Sourcing and Management

- Key Raw Materials :

- PP Spun-Bound Polypropylene Roll (Outer and Inner Layers)

- Melt Blown Polypropylene Roll (Filter Layer)

- Polyamide Elastic Band Reel (Ear Loops)

- Packaging Material

- Raw Material Consumption : The report estimates 13,250 kg of raw material per annum for 7.2 million masks production.

- Supplier Identification: Research and identify reliable suppliers for each raw material. Quality and consistent supply are crucial.

- Inventory Management: Plan for raw material storage and maintain optimal inventory levels to avoid production delays and excess stock.

6. Manufacturing Process – Step-by-Step

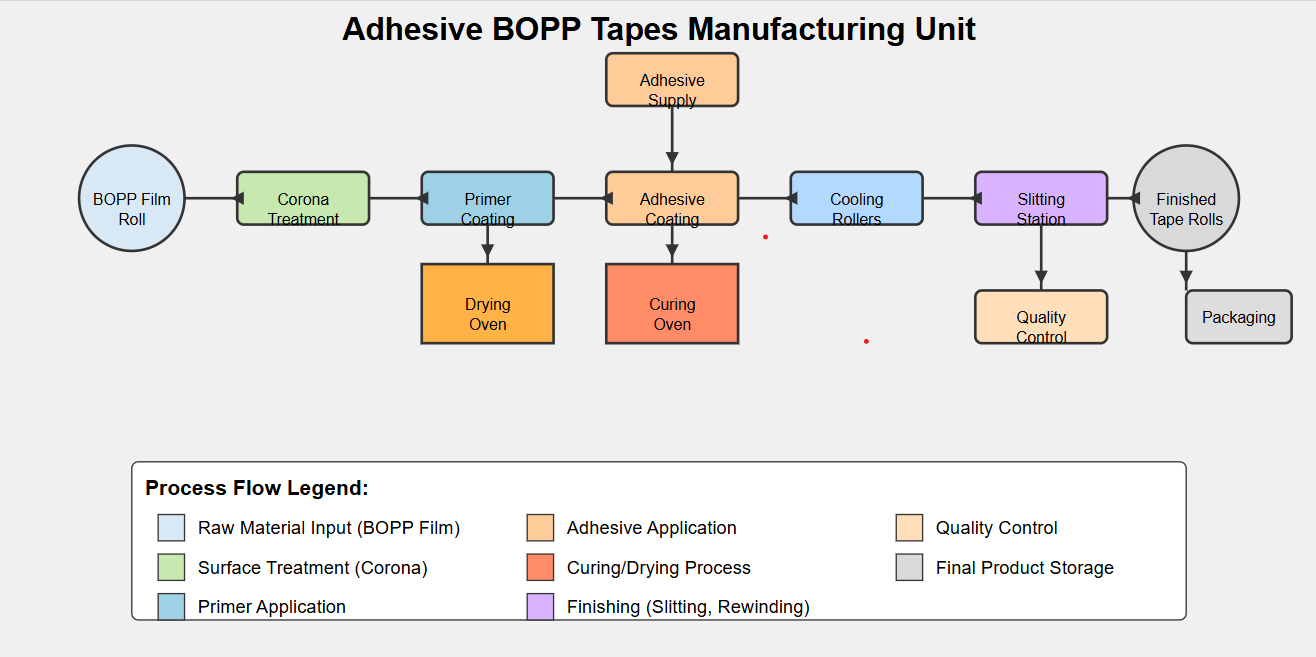

- Roll Feeding: Load PP Spun-Bound and Melt Blown Polypropylene rolls, and Polyamide Elastic Band Reel into the machine’s feeding sections.

- Unrolling and Layering: The machine unrolls and layers the three fabric sheets.

- Edge Welding: Layers are welded at the edges to form a continuous mask material.

- Folding: The welded material is fed to a folding section to create mask folds.

- Hot Pressing: Folds are set using a hot press.

- Cutting and Welding: Material is cut into mask widths, and edges are welded to form mask bodies.

- Ear Loop Welding: Ear loops (cut from Polyamide Elastic Band) are welded onto each mask body in dedicated welding stations.

- Packaging : Surgical masks are fed into a packaging machine for plastic packaging, followed by carton packing.

7. Quality Assurance and Control

- Raw Material QC: Inspect incoming materials for quality and specifications.

- In-Process QC: Monitor production at each stage for defects (welding issues, layer alignment, ear loop attachment).

- Finished Goods QC: Final inspection of masks for quality, dimensions, and packaging integrity. Consider tests for:

- Filtration Efficiency (Bacterial Filtration Efficiency – BFE, Particle Filtration Efficiency – PFE)

- Breathability (Delta P)

- Fluid Resistance (Splash Resistance) – if targeting higher grades of masks.

- Standards and Certifications: Explore relevant quality standards (e.g., ISO 13485 for medical devices) and certifications (like CE marking, FDA approval if exporting) to enhance credibility and market access.

8. Manpower and Training

- Labor : The report suggests:

- 2 Skilled Workers: ₹10,000/month each

- 4 Unskilled Workers: ₹8,000/month each

- Administrative Staff :

- 4 Administrative Staff: ₹12,000/month each

- Training: Provide training to operators on machine operation, maintenance, and quality control procedures. Train administrative staff on sales, marketing, and operations management.

9. Marketing and Sales Strategy

- Target Market :

- Drug Stores (Historically dominant, but online growing)

- Hospitals & Clinics

- Online Stores (Fastest growing channel)

- Distribution Channels:

- Direct Sales to Hospitals and Clinics.

- Distributors and Wholesalers for wider reach.

- Online Sales Platforms (e-commerce websites, marketplaces).

- Retail Partnerships (pharmacies, supermarkets).

- Competitive Advantage : Focus on:

- High Quality

- Strong Financial Position (manage costs effectively)

- Use of Modern Technology (efficient machines)

- Marketing Activities:

- Develop a brand identity and packaging.

- Online marketing (website, social media).

- Trade shows and industry events.

- Build relationships with distributors and retailers.

10. SWOT Analysis – Understanding Your Business Environment

- Strengths: Huge Market, Strong Financial Position, High Quality, Growing Private Hospital Sector, Use of Modern Technology.

- Weaknesses: Expansion in healthcare Masks capacity may exert pricing pressure, Untapped Rural Markets, Less Advertisement Effort, Inability to pass on full impact of any cost increase.

- Opportunities: Demand for Surgical Masks to stay healthy, Demand for healthcare Masks to grow by European, Customized medical masks to provide growth driver, Government Initiatives and Policies, E-Commerce.

- Threats: Highly Competitive Market, Volatility of Profit.

Conclusion

Setting up a 3-ply surgical mask manufacturing unit is a complex but potentially lucrative venture. By leveraging detailed project reports like the one provided, you can gain a significant head start. This blueprint emphasizes thorough financial planning, efficient operations, quality control, and strategic marketing. Remember to adapt this guide to your specific circumstances, conduct further market research, and seek expert advice to navigate the regulatory landscape and ensure your business thrives in this essential industry.

Post Comment

You must be logged in to post a comment.