Business Setup Info

Acrylic Sheets, Acrylic Signage Board, Aluminium Composite Panels, Architectural Signage, Break-Even Point, business idea, business setup, Capital Investment, Channel Bending Machine, CNC Router Machine, Color Paste, Corporate Branding, Curing Glue, Debt Service Coverage Ratio (DSCR), Design & Planning, Directional Signage, Durability, Financial Projections, investment in business, LED Lights, Light Effects, Lobby Signage, Manufacturing Unit, Market Potential, Marketing Strategies, Packaging, Power Supply Drivers, Pre-feasibility Report, Production Process, Profit Margins, Project Concept Development, Project Cost, Project Report, Quality Testing, Raw Material Requirements, Sales Turnover, Small-Scale Unit, Start-Up Investment, Term Loan, UV Curing Machine, Waterproof, Weatherproof, Working Capital

msaoji

0 Comments

A Comprehensive Guide to Setting Up an Acrylic Signage Board Manufacturing Unit

Are you looking to invest in a profitable, durable, and innovative signage solution? This blog post provides an in-depth look into the pre-feasibility and project report for an Acrylic Signage Board Manufacturing Unit. From project concept development to detailed financial projections, manufacturing processes, raw material requirements, and more, this guide covers everything you need to know to kick-start your venture.

Why Choose Acrylic Signage Boards?

Acrylic signage boards are renowned for their durability, waterproof and weatherproof properties, and high-quality cast finish. These sign boards not only mimic the elegance of traditional glass but also offer versatility in design. With various forms available—transparent, opaque, or router-cut—acrylic signs are ideal for corporate branding, lobby displays, directional signage, and architectural applications.

Key benefits include:

- Durability & Weather Resistance: Long-lasting material suitable for both indoor and outdoor use.

- Versatility in Design: Customizable with various finishes and colors.

- Enhanced Visual Appeal: Innovative light effects such as smudge, smooth, and clear due to acrylic’s light-permeable properties.

- Portability: Lightweight and easy to install, making them perfect for dynamic corporate environments.

Project Overview and Objectives

The pre-feasibility report is designed to help potential entrepreneurs evaluate the investment required for setting up an acrylic signage board manufacturing unit. The report covers:

- Project Concept & Development: Detailed steps from product design to manufacturing.

- Start-Up Requirements: Capital investment, working capital needs, and loan details.

- Marketing Strategies: Approaches to brand positioning and product pricing.

- Financial Projections: Expected sales turnover, break-even analysis, profit margins, and repayment schedules.

- Management & Operations: Information on labor, plant machinery, and power requirements.

Project Snapshot

- Project Cost: Rs. 21.11 Lakhs

- Means of Finance:

- Term Loan: Rs. 13.5 Lakhs

- Own Capital: Rs. 2.11 Lakhs

- Working Capital: Rs. 5.5 Lakhs

- Break-Even Point: 43%

- Pay Back Period: 5 Years

- Employment Generation: Approximately 16 persons

- Project Implementation Period: 5-6 Months

- Estimated Annual Sales Turnover: Rs. 140.22 Lakhs (at maximum capacity)

Manufacturing Process and Plant Setup

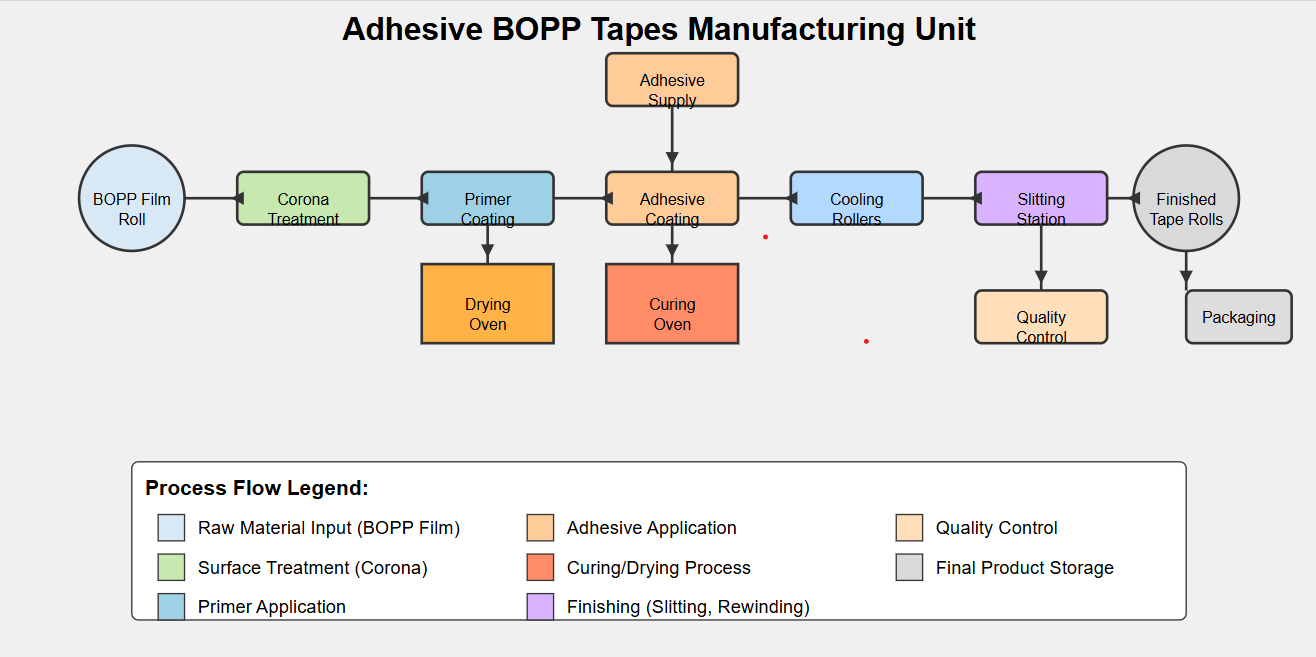

Step-by-Step Production Flow

- Design & Planning:

The process begins with designing the signage concept on a computer. This includes deciding the layout and text for the sign board. - Material Preparation:

- Acrylic Sheets: Used for creating the core design elements.

- Additional Raw Materials: Aluminium composite panels, LED lights, color paste, curing glue, and power supply drivers.

- Machinery in Action:

- Channel Bending Machine: This machine bends the acrylic sheet to form the desired letter design.

- CNC Router Machine: Used for precise cutting of the alphabets from the acrylic sheets.

- UV Curing Machine: Post-cutting, the letters are cured under UV light for approximately 2 hours, ensuring longevity and enhanced finish.

- Finishing Touches:

- LED Installation: After curing, LED lights are installed in the acrylic letters.

- Quality Testing: Rigorous testing of wiring and power supply is conducted to ensure safety and quality.

- Packaging: Once all processes are complete, the final product is packed securely and made ready for market distribution.

Essential Machinery and Tools

- Channel Bending Machine

- CNC Router Machine

- UV Curing Machine

These machines are integral to achieving high precision and quality in production.

Raw Material Requirements and Costing

The manufacturing process requires high-quality raw materials, and the report outlines the specific requirements and their respective costs.

Major Raw Materials Include:

- Acrylic Sheets (8’x4′): Primary material for the board.

- Aluminium Composite Panels: For additional structural integrity.

- LED Strips: Essential for illumination and aesthetic appeal.

- Color Paste & Curing Glue: Used for design detailing and bonding.

- Power Supply Drivers: Critical for LED functionality.

Cost Computation

- Total Raw Material Cost (at 100% capacity): Rs. 7,475,000

- Cost per Square Foot: Rs. 249

This cost structure helps in estimating production expenses and setting competitive sale prices.

Detailed Financial Projections

The project report includes comprehensive financial details that cover:

Cost Breakdown:

- Plant & Machinery: Rs. 14.00 Lakhs for essential machines.

- Furniture & Fixtures: Rs. 1.00 Lakh.

- Working Capital: Rs. 6.11 Lakhs.

Financial Highlights:

- Gross Sales Projection: Ranges from Rs. 81.13 Lakhs (at 50% capacity) to Rs. 140.22 Lakhs (at 70% capacity).

- Gross Profit Margins: Expected to rise from 32.19% to 36.85% as production capacity increases.

- Net Profit After Tax: Projected profit growth from 1.6% to 10.2% over five years.

- Debt Service Coverage Ratio (DSCR): Averaging 2.75, indicating healthy financial sustainability.

Loan Repayment and Cash Flow:

- Repayment Schedule: Structured over a period with quarterly repayments, ensuring manageable cash flow.

- Electricity and Fuel Costs: Detailed computation ensures energy expenses remain controlled.

Market Potential and Industry Trends

With increasing competition and the need for effective advertising post-liberalization, the demand for acrylic signage boards is on the rise. Key market drivers include:

- Corporate Branding: Companies are investing heavily in office aesthetics and directional signage.

- Architectural and Lobby Signage: Enhanced visual appeal and durability make acrylic boards a preferred choice.

- Technological Advancements: Integration of LED lights and advanced manufacturing processes add to the product’s competitiveness.

Entrepreneurs entering this market can leverage these trends to position their products effectively, meet customer demands, and capture significant market share.

Final Thoughts

Investing in an Acrylic Signage Board Manufacturing Unit offers a promising opportunity for aspiring entrepreneurs. With robust financial projections, state-of-the-art manufacturing processes, and a clear market demand, this venture is well-poised for success.

Post Comment

You must be logged in to post a comment.